Daily optimisation of the use of the producer portfolio

Daily, Energie AG from Upper Austria is optimizing the use of its producer portfolio, including storage facilities and an additional integration of industrial waste heat. As well as the plant availability, external variables such as electricity prices and heat demand forecasts are considered in the mathematical optimization.

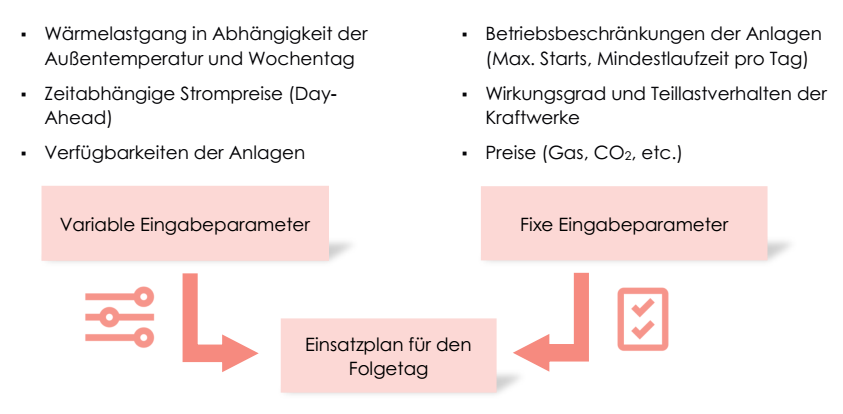

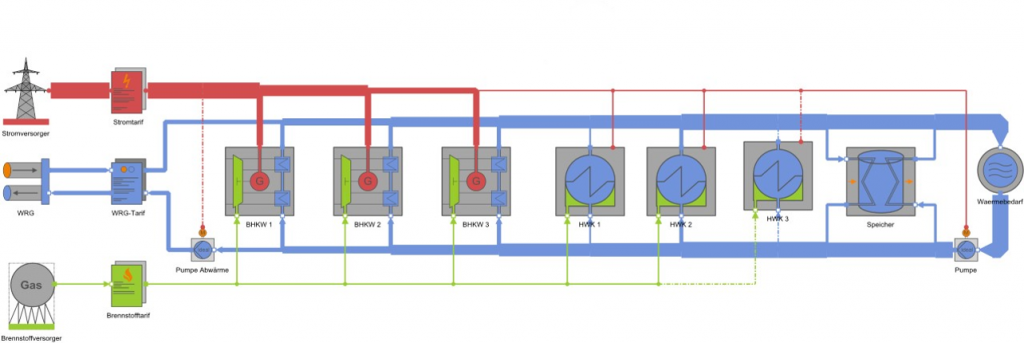

The energy system of the district heating supplier “Energie AG Oberösterreich Wärme” for the Kirchdorf location comprises coupled systems consisting of three CHPs, three boilers and a heat accumulator. In addition, the option consists of purchasing waste heat from a nearby cement plant. The company supplies around 1,300 customers with district heating. The operating mode of the available heat generators depends on the following factors and operating parameters and is considered in the application planning of TOP-Energy®:

On one hand, the model developed (see figure below) should be complex enough to map all important and decisive influencing variables. On the other hand, it should be as fast and user-friendly as possible for the operating personnel. As a result, users receive a daily deployment plan for the various heat generator units, stating the forecast heat input, the daily operating and production costs. The associated temporal resolution is one hour. The results are output as a report and can then be electronically archived. The software can also be used to simulate possible price models with suppliers and customers. The simulation achieves in practice a high agreement between the forecast and the actual heat demand. The deviation is usually less than 2 %. In addition, operating costs have been noticeably reduced. The investment in software support, including licensing and customization services, could thus be amortized within a few months.

Title: Ensure cost advantages in operation. Mathematical Optimization of Operations

Authors: Josef Füreder; Stefan Kirschbaum; Johannes Schliesser

ISSN: 0949-166X

Jg.44, 2015, Nr.7/8

S.20-23